About

AvasaralaTECHNOLOGIES LIMITED

It was in the year 1985 that we set foot on the engineering

arena, predominantly in the field of high technology

engineering. A thirst for excellence and an eye for innovation

saw us diversify into vastly different areas of Nuclear Power,

Factory Automation, Engineering Construction, Space and

Healthcare.

It was only a matter of time before we consolidated our position across India and overseas. Delivering optimal technological solutions in critical areas with our comprehensive capabilities, our mission is to continue contributing towards engineering excellence... We are Avasarala Technologies.

It was only a matter of time before we consolidated our position across India and overseas. Delivering optimal technological solutions in critical areas with our comprehensive capabilities, our mission is to continue contributing towards engineering excellence... We are Avasarala Technologies.

Test Data

NUCLEAR POWER EQUIPMENTS

Consistent customer demand propelled us at Avasarala into the highly niche segment of Nuclear Power Machinery.The venture paid off, and even the most complex parts of the critical nuclear reactor fuel loading systems have been successfully met.The expertise shown in refurbishing work for the nuclear power reactors have won accolades in the industry and have set new benchmarks in the international arena. We now have significant expertise in manufacture and supply of critical area equipment, including fuel handling systems.

.jpg)

Fuelling Machine Head

- For both 220MWe and 700MWe reactors

- Remote Operation of Nuclear Fuel Loading / Unloading

- Assembled with High Precision Components & Tested to high accuracies.

- Works in High Radiation, High Pressure, Hot Zone

- Fail Safe Equipment works without shutting down during entire life cycle of Reactor

.jpg)

Control Rod Drive Mechanism

- Critical Equipment for Reactor Control

- Manufactured & Tested to high accuracies

- Life cycle test carried out for product validation on a Test Station.

.jpg)

Radiation Shielding Window

- Viewing Window from Safe area to Radiation Area

- Fabrication, Machining, Assy, Testing and Safe Transport

- L x W x H : 1.9 x 1.85 x 1.8 Mtrs.

- Weight after assembly 9.12 Tons.

- Assy of Glass blocks of densities ranging from 2.5 gm/cc to 5.2gm/cc and filled with Paraffin Oil.

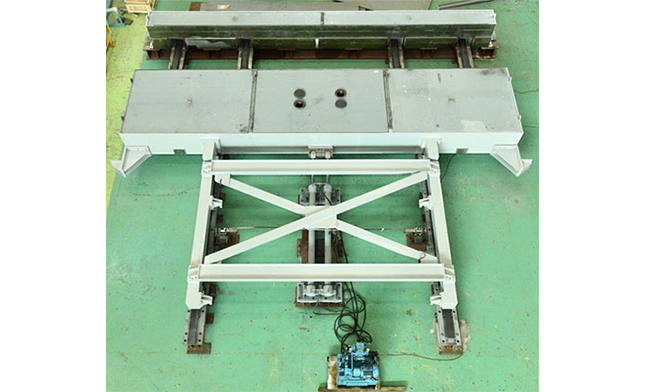

Roll On Shield and Doors

- Equipment to Isolate between Service Area and Radiation Area. Covers an area of 9Mtr x 5 Mtr

- Operates with Dual Hydraulic Cylinder with a stroke length of 6 Mtrs.

- 35 Ton Fabrication, Machining & Testing to high accuracies.

.jpg)

Cadmium Sandwiched Tubes

- Control Rods and Shutoff Rods used to control Reaction Rate in the Reactor.

- Two SS Tubes of 5.5 Mtr length Sandwiched on a Cadmium sheet to a Diameter of 112 mm.

.jpg)

Shielding Plugs & Sealing Plug Assemblies

- Exclusive line for Manufacture, Assembly & Testing

- Sourcing of special grade stainless steel

- 100% interchange ability, Functional Test Done

- Established Hard Chrome Plating Facility

- Supplied 2500 sets

.jpg)

Double Strand Pilgering Machine

- For Reduction of thin wall Zirconium and High Alloyed Stainless Steel Tubes, with outside diameter ranging from 10 - 20mm

End Plate Welding System

- Automated Resistance Welding of 37 elements Fuel bundle End Plates - 540MWe PHWR.

- Indigenously developed Pick & Place Electro-Pneumatic Robot. Automated Transfer of loaded Fixture to Welding Station.

.jpg)

Uranium Drum Handling System

- Automated Handling, Powder Unloading, Washing, Contamination Check, Volume Reduction

- Design, Approval, Procurement, Assembly, PLC Logic Development, Testing as per French Standards.

- Uranium Ore Handling Equipment commissioned at AREVA, France.

Waste Fuel Handling Equipments:

.jpg)

Storage Module & Alignment Mechanism

- Storage Module is a circular Tank with dia 3.2 x 5.6 mtrs. Located in a Concrete Pit. Spent fuel is stored in 300 Lattice tubes. Alignment Mechanism positions the loader over any of the Lattice Tubes.

.jpg)

Remote Operated Maintenance Vehicle

- Moving & Retrieving Pumps from Pump Enclosures

- Unmanned Operation & Remotely controlled

- Automated removal of Pumps from the enclosure

- Replacement of pump back in to location after maintenance

- Total Travel distance 40 mtrs

.jpg)

Spent Fuel Transport Container

- Filter Cart Transfer System, Fabrication, Machining, Assembly, Testing.

- Shielded Transport Container

- Supplied to Energy Solutions, USA

.jpg)

Low Level Liquid Waste Processing System

- Fabrication, Assembly, PLC Logic Development.

- Testing as per US Standards

- Supplied and Commissioned at China.

Test Data

Our

Products & Services

Products & Services

- Nuclear Power

- Factory Automation

- Aerospace & Defence

- Space Products

- Medical Equipments

- R & D Institutions

Copyright © Avasarala Technologies Limited. All rights reserved | Login